Agricultural Sprayer Drone

Overview

The Challenge

Pakistani farmers needed precision spraying technology, but commercial agricultural drones cost $6,000-$10,000—forcing continued reliance on dangerous, wasteful manual methods.

Our Solution

Custom-built agricultural drone delivering commercial-grade performance at 65% lower cost, making precision agriculture accessible to resource-constrained farming operations.

Results & Impact

Reduced spraying time from 16 to 7.5 minutes per acre

Decreased water usage from 59L to 10L per acre through precision application

System cost of $3500 versus $8500+ for commercial alternatives

ROI within 1.5 years for 200+ acre operations

The Market Problem

Pakistani farmers face a painful choice. Manual pesticide spraying exposes workers to toxic chemicals, wastes product through poor coverage, and delivers inconsistent results. But commercial precision spraying drones cost $6,000-$10,000—completely out of reach for most agricultural operations.

The global agricultural drone market is growing rapidly, but that growth isn't reaching the farmers who need it most. They're stuck with methods that are dangerous, inefficient, and increasingly uncompetitive.

Ready to Transform Your Business?

Let's discuss how we can help you achieve your goals with our innovative solutions.

Get Started TodayThe Solution

Big0's research team, led by Hassan Kamran (ORCID: 0009-0005-3034-1679), developed a precision agricultural drone that delivers commercial performance at a price Pakistani farmers can actually afford.

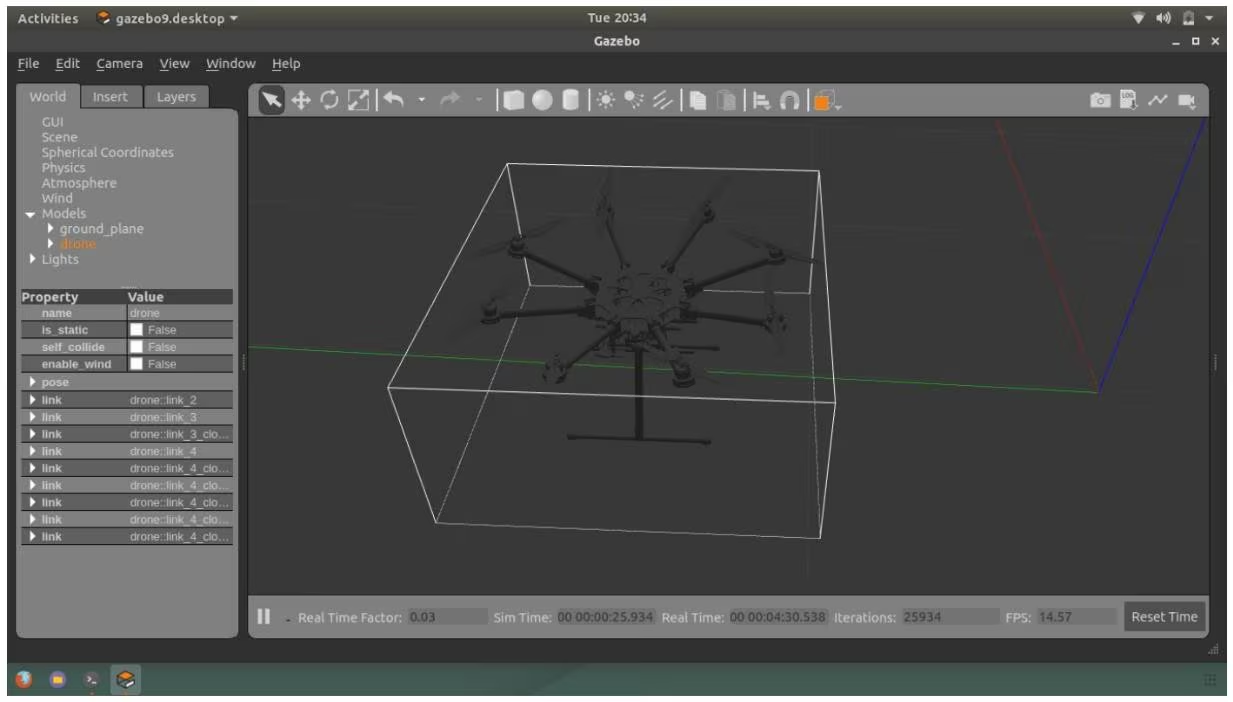

The system uses simulation-driven development—virtually testing configurations before physical construction—to optimize both performance and cost. The result: an 8-motor drone with extended flight time, spray capacity, and precision application that puts chemicals exactly where they're needed.

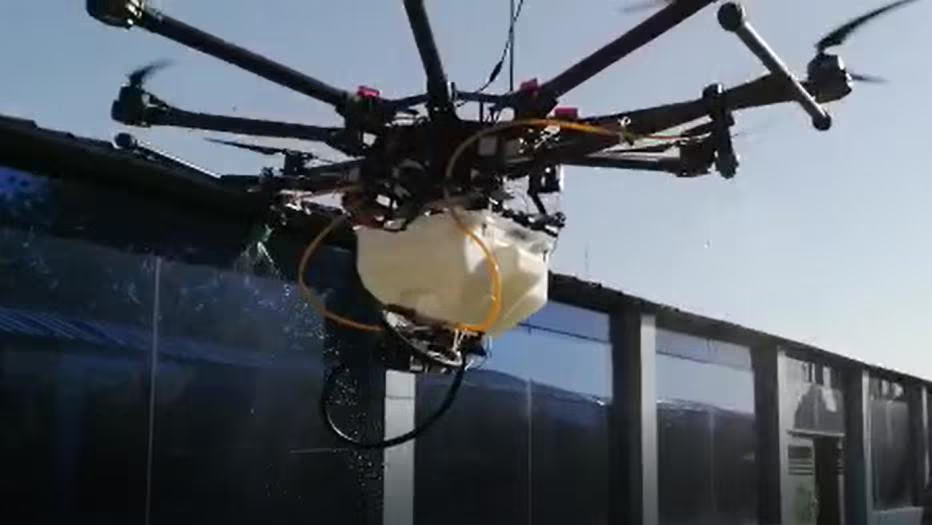

Custom octocopter with integrated precision spray system

Custom octocopter with integrated precision spray system

Anti-drift nozzle design keeps spray on target. The modular construction enables easy maintenance and component replacement without specialized tools or expertise.

The Results

Field testing validated performance across diverse Pakistani agricultural conditions. The system eliminates direct operator exposure to harmful chemicals while delivering spray accuracy that manual methods can't match.

Field testing demonstrating precision coverage

Field testing demonstrating precision coverage

Coverage is faster and more uniform. Water and chemical usage drops dramatically through precision application. And at roughly $3,500, the economics work for operations that could never justify commercial drone prices.

The project demonstrates that advanced agricultural technology can be made accessible without compromising performance. The approach—simulation-driven development, cost-optimized engineering, local manufacturing considerations—provides a template for democratizing precision agriculture throughout South Asia and similar markets.

Technologies Used

Ready to Transform Your Business?

Let's discuss how our AI-powered solutions can drive your growth

Schedule Your AI Consultation